10,000 Ton Per Year

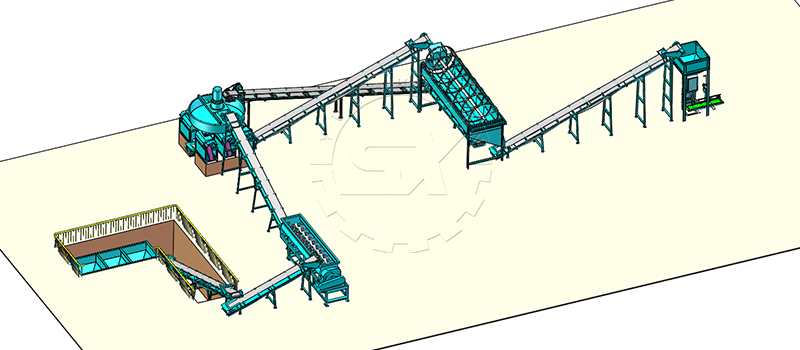

Granular Compound Fertilizer Production Line

For a 10,000-ton-per-year granular compound fertilizer production line, MFP recommends a double roller extrusion granulation method. Raw materials that are sensitive to heat are particularly suited to extrusion granulation. According to capacity, double roller extrusion granulation is perfect for small-scale compound fertilizer factories. It is a type of dry granulation. Thus, you can skip the procedure of drying and cooling because the end product is always dry. As a result, it can save energy consumption. With this production line, you will produce little waste and you can reduce the investment and production costs.

The extrusion granulation method can produce particles with high strength, good appearance, uniform sizes, and adjustable shapes. Moreover, it can add micronutrients according to different needs.

Raw Materials For Making Granular Compound Fertilizer

A wide range of raw materials can be granulated by the extrusion method, including calcium carbonate, ammonium chloride, ammonium sulfate, calcium nitrate, limestone, gypsum, NPK compound fertilizer potassium chloride, potassium sulfate, heavy calcium, urea, phosphate ore, etc.

4 Stages of making compound fertilizer

Why dry granulator is suitable for granular compound fertilizer production line?

Double roller granulators are now mainstream in dry granulation. For some compound fertilizers with low nitrogen content and high water solubility. It is obviously more suitable than drum granulating. What’s more, as we mentioned before, some chemical raw materials are not heat-resistant. During the drying process, the temperature will rise and destroy some elements.

According to the characteristics of ammonium sulfate and ammonium chloride, the use of dry granulation can extrude the air between the crystals. The moisture and strength of particles can meet the requirements of fertilizer and are easy to transport. Meanwhile, the use of double roller granulators can achieve automated production.

Service of MFP Provides

MFP company provides our customers with a 365-warranty, so you can contact us if there’s any problem during the operation process. Furthermore, if you have larger capacity needs, our sales manager will give you a detailed offer about this compound fertilizer granulation line.