What Is Commercial Composting Equipment?

What Is Commercial Composting Equipment?

What is a commercial composting system?

A commercial composting system refers to a large-scale facility designed to process livestock and poultry manure through the composting process. Through the composting process, organic matter will become nutrient-rich soil amendment and we call it compost.

Now, more and more authorities start to realize the necessity of making compost. Because organic waste such as animal manure, food scraps, agricultural residues, or other biodegradable materials can contribute to environmental issues if people simply send them into landfills.

For example, the ghastly bad smell, moreover, the methane gas is a huge crisis to our environment. Therefore, many businesses, municipalities, and organizations begin to seek composting technology to make commercial composting systems.

Here are the typical steps of the commercial composting system:

- 1

Collecting Raw Materials: Of course the first step is to collect agricultural waste, and animal waste, including manure and even carcasses.

- 2Preprocessing: The collected materials may undergo preprocessing to remove impurities like plastic or non-compostable materials. This step helps maintain the quality of the compost.

- 3

Composting: The best moisture of raw materials is 60%. So you have to dry your raw materials a little bit if there’s too much water content. Because this can determine whether you can make compost successfully. Then you can place the organic waste in a controlled environment, such as large windrows (long rows) or in enclosed fermentation tank. The composting process relies on microorganisms breaking down the organic matter.

- 4

Turning and Aeration: Throughout the composting process, the material needs periodic turning or mixing to enhance aeration. This promotes the growth of beneficial bacteria and ensures even decomposition. You can achieve this by an industrial compost machine.

- 5

Maturation: Once the initial composting process is complete, the partially decomposed material is allowed to mature or cure. It undergoes further decomposition and stabilizes to create a high-quality, nutrient-rich compost.

- 6

Screening: After maturation, you need a screener to remove large contaminants or particles. A rotary screener can help you produce a consistent and fine-textured final product.

- 7

Distribution and Use: Finally, you get high-quality compost, and you can sell them to dealers or local farmers. It is a good soil amendment because it can improve soil structure, fertility, and water retention.

Commercial composting systems play a vital role in waste management and environmental sustainability. They divert organic waste from landfills, reduce greenhouse gas emissions, and produce valuable compost that enriches soils and reduces the need for chemical fertilizers.

What equipment is used in composting?

You will need a solid-liquid separator, a compost turner, and a rotary screener in composting.

A solid-liquid separator can help reduce the moisture of your raw materials. As fresh chicken dung has high water content, a solid-liquid separator made in the MFP factory can reduce the water content from 80% to 50-60%. After dehydrating, the raw materials are ready to make compost. And this is also the most important procedure. Turing the compost is the most useful way to aerate the compost and provide enough oxygen. Thus speeding up the organic matter decomposition.

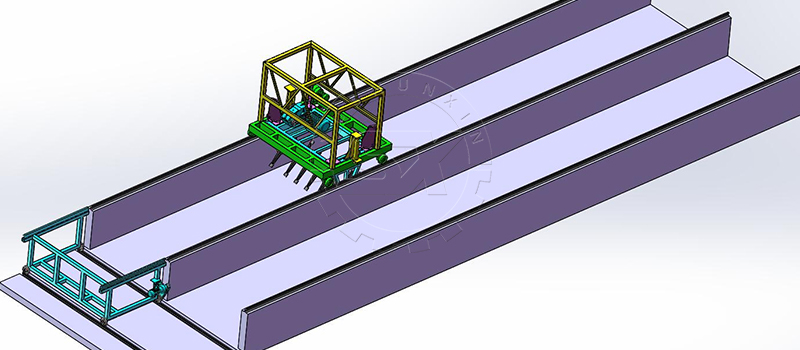

Commnercial Groove-type Compost Turner

For those who have limited factory area, we recommend groove type and wheel type compost turners. You need to transport materials in grooves and then compost turners will turn manure in grooves. Still, there’s a difference between the two compost turners. That is the wheel type can turn compost with 3-30m width and 1.5-3m depth. Therefore, one wheel type compost turner can handle one big enough groove.

Commercial Self-propelled Compost Equipment

Except for groove type, we also manufacture self-propelled compost turners for those who own vast areas and don’t need to build grooves. They work on the ground. Easy to operate and can crush and turn the compost at the same time thanks to the paddles on the beam.

Large-scale In Vessel Composting Machine

If you worry about the bad working environment and want to deal with compost in the least smelly and dirty way. Fortunately, you have another option! Our in vessel composting machine (also called compost fermentation tank) is the fastest and most-efficient way to decompose compost. It can kill harmful bacteria in 10 hours by electricity in an enclosed tank. After decomposition, all you need is to wait for its maturation (one week is enough).

Above are three types of composting machines innovated by the MFP factory. With a solid-liquid separator, a compost turner, and a rotary screener, you can start your compost business.

Commercial composting equipment for sale

MFP factory has been a renowned fertilizer machine manufacturer in China for 18 years. We can customize all types of commercial composting equipment you need. You can tell us your expected capacity and factory size. And our sales manager will provide you with a detailed project design as well as a drawing design as soon as we can.

Furthermore, we can give you factory prizes. Up to now, we have built business relationships with clients all over the world. Welcome to send emails to learn more about our cases for our clients. We hope to help you produce high-quality fertilizer and promote sustainable development.