Bio Organic Fertilizer Production Line

Benefits Of Making Bio Organic Fertilizer

MFP factory manufactures a whole set of bio organic fertilizer equipment.

Bio-organic fertilizer integrates organic fertilizer, inorganic fertilizer, and microorganisms, which is more conducive to exerting the advantages of fertilizer. It is rich in organic matter and a certain amount of nitrogen, phosphorus, potassium, and trace elements. At the same time, the increase in microbial reproduction can help improve the soil and protect the environment.

Bio-organic fertilizers can continuously release nutrients after microbial decomposition, and effectively release various nutrients required by crops during the growth period. Moreover, bio fertilizers help maintain the normal fertility of the soil and keep it natural.

Biofertilizers are chosen over chemical fertilizers since they are non-toxic and contain organic elements, whereas chemical fertilizers contain chemicals that are hazardous to the soil. Long-term use of chemical fertilizers will lead to changes in soil quality and low soil regeneration capacity, thereby affecting the quality of agricultural products.

Next, we will introduce our bio organic fertilizer production line.

What Is The Difference Between Bio Fertilizer & Organic Fertilizers?

Availability And Extent Of Bio-Organic Fertilizer

Bio-organic fertilizer refers to a type of organic fertilizer that combines specific functional microorganisms. When making compost, you need add microorganisms in it.

You can use livestock and poultry manure, crop straw, etc as compost materials. After the beneficial microorganisms in the bio-organic fertilizer enter the soil, they form a symbiotic multiplication relationship with the microorganisms, inhibit the growth of harmful bacteria, and transform them into beneficial bacteria. They can interact and promote each other. Furthermore, microorganisms can produce a large number of metabolites during the growth and reproduction process. Bio-organic fertilizer recycles agricultural waste and reduces environmental pollution. It is safe and non-toxic to people, livestock, and the environment. Thus, making bio organic fertilizer is good for the environment.

MFP also sells a whole set of organic fertilizer production line. Organic fertilizer mainly refers to fermented and decomposed carbon-containing organic materials derived from plants or animals. Its function is to improve soil fertility, provide plant nutrition, and improve crop quality. It is processed from biological substances, animal and plant wastes, eliminating the toxic and harmful substances in them, and rich in a large number of beneficial substances, including a variety of organic acids, peptides, and rich nutrients such as nitrogen, phosphorus, and potassium. Not only can it provide comprehensive nutrition for crops, but also have a long fertilizer effect. It can increase and renew soil organic matter, and promote microbial reproduction.

How To Produce Bio Organic Fertilizer?

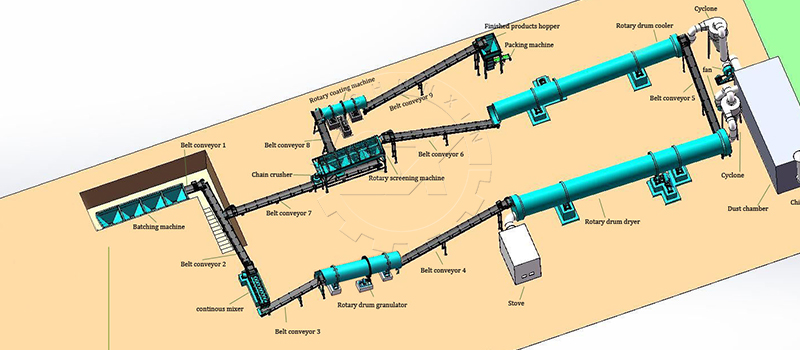

Composting and granulating are the two main processes in the bio-organic fertilizer production line.

Natural fermentation can complete the composting process, but bio organic fertilizer is recommended to speed up the process. You also need granulators in the granulating process.

MFP will introduce you to these two types of bio organic fertilizer making machines in the following paragraphs.

Machines To Compost Bio Organic Fertilizer

One common way to ferment bio organic fertilizer is by turning the compost. When turning compost, you have to take the following problem into consideration. It is the size of the compost. If the bio organic fertilizer compost is too small, the heat will be easily lost, and it will be hard to generate heat. On the contrary, if it is too large, the air will not easily penetrate into the inner part, causing a deficiency in air and oxygen.

If your composting operation area is large enough, a crawler type compost turner is a good choice. It is equipped with a steel drum with paddles and a water pipe on the front of the machine. You can fully flip the compost and spray water on it to add moisture and speed up fermentation. Also, if your factory has been constructed with grooves, then groove-type compost tumblers can help you ferment raw materials efficiently.

There are two composting machines working in a groove provided. The first is a normal groove type compost turner, and the second is wheel type composting machine. The latter fits in large-scale compost factories and is easy to operate.

Bio Organic Granulator Machine Manufacturer

Generally, there is no need for granulating bio-organic fertilizers, especially solid microbial fertilizers that absorb a large number of bacteria. Both granulation and drying processes will cause a considerable loss of microorganisms.

Many bio organic fertilizer manufacturers choose to make pellets because the price of pellets is higher than that of powder and because pellet fertilizers are more attractive and easier to transport.

There is dry granulation and wet granulation. The first method belongs to physical granulation technology without heating up and for the second method you need dry pellets at high temperatures.

First, if you choose dry granulation, you can use a flat die granulator to make pellets. Moreover, you can add microorganisms directly to the powder before granulation. Nevertheless, the end product of a flat die granulator is columnar. You need a polishing machine if you need round particles.

If you choose the wet granulation method, a pan granulator and drum granulator can meet your requirements. Usually, a pan granulator can assemble a small-scale production line, such as one ton per hour. And you can use drum granulators in large-scale production. Both granulators need to dry pellets with rotary drum dryers and rotary drum coolers to reduce the moisture of the pellets. Thus, you can pack and store fertilizer pellets for a long time.

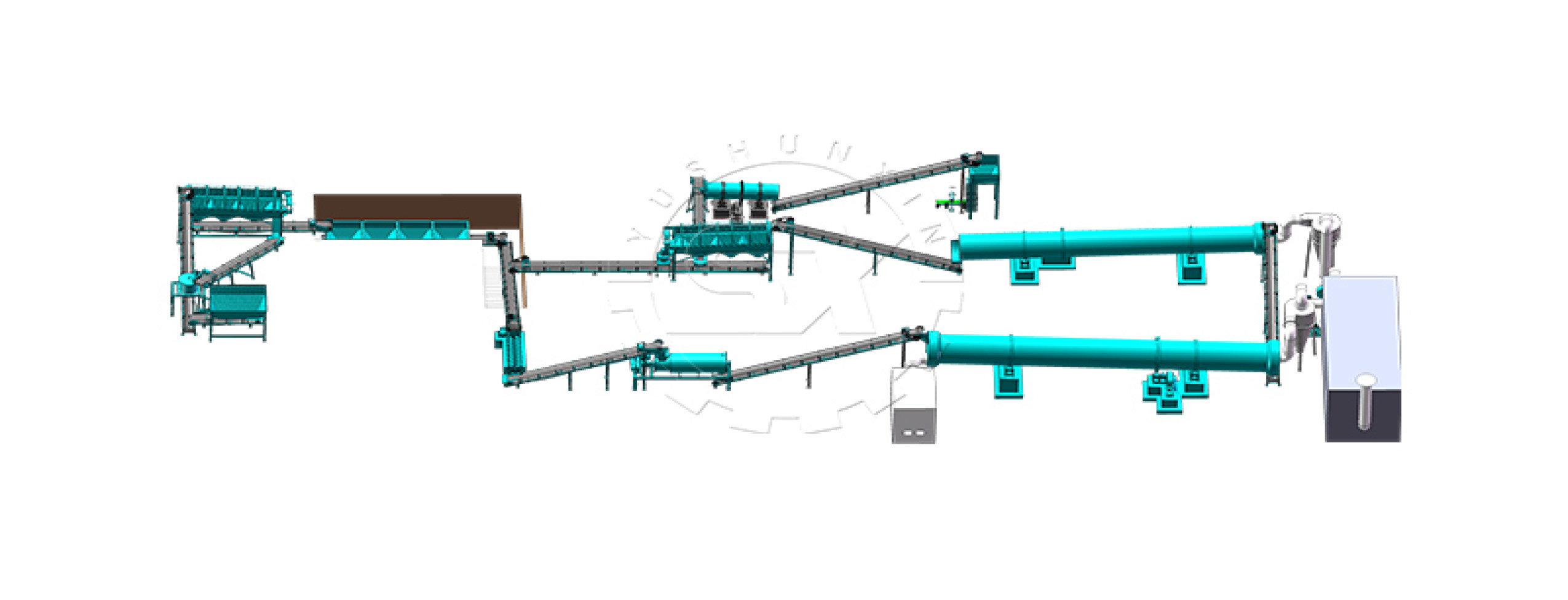

How To Design A Plant Of Bio Organic Fertilizer?

If you plan to start a plant of bio organic fertilizer with a capacity of 5 tons per hour(about 13,000 tons per year), it will need 2500㎡(it includes the area of compost and granulation factory).

In total, it will take you about $ 150,000 to purchase the whole set of bio organic fertilizer production lines.