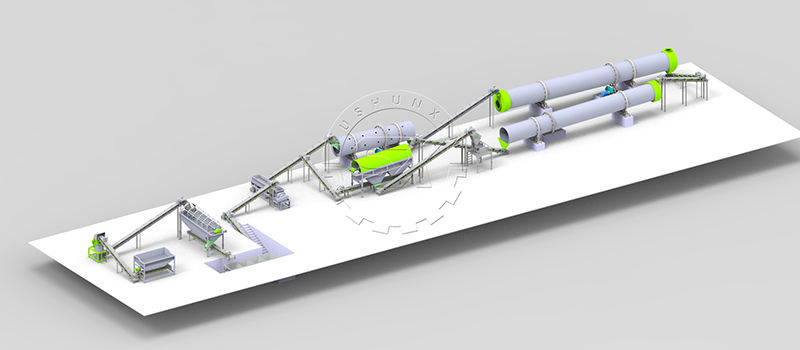

Compound Fertilizer Production Line

3 Types Of Compound Fertilizers can make

MFP classifies compound fertilizers into the following 3 types. Our factory manufactures various fertilizer equipment. Therefore, you can produce the three types of compound fertilizer with our machines.

Compound Fertilizer Production Line

In compound fertilizer production line, granulation is one of the most important steps.Because the shape and size of end product determine the prize of your compound fertilizer pellets.

In the current production process, the granulation are inclined to produce scarring and dust problems, which will have a more serious impact on the ball rate. You should clean equipment regularly, in case it will affect mutual quality directly.

To prevent scarring and dust generation, you need to take the following factors into consideration.

Compound Fertilizer Granulation Process

There are drum granulation, disc granulation, and dry extrusion granulation. Each granulation process has certain advantages.

Drum Granulation

Drum granulation is the most widely used in the type of compound fertilizer production equipment. The main way of working is agglomerated wet granulation, through a certain amount of water or steam. Then raw materials in the cylinder will begin the rotational movement. At last, the material particles between the extrusion pressure will agglomerate into a ball.

Disc Granulation

The process principle of disc granulation is that all raw materials are mixed into the disc, and the disc makes the materials agglomerate into balls by rotating. Disc granulation has an advantage of simple equipment and operation. Moreover, pan granulators need low investment.

However, disc granulators are more suitable for small-scale production, and it has low efficiency compared with drum granulators. Besides, the formula has restrictions. Because raw materials should be viscous , only suitable for making low concentration compound fertilizer.

Extrusion Granulation

Extrusion granulation is a dry granulation process in which solid materials rely on external pressure for agglomeration. It has the following advantages:

(1) The production process generally does not require drying and cooling process, especially adapted to heat-sensitive materials at the same time can save investment and energy consumption.

(2) Simple operation, no emissions during production.

But the extrusion granulation method also has shortcomings:

Due to the high pressure, the rollers on extrusion granulator are easy to wear and tear. Therefore, you need to change the wearing parts regularly.

The capacity of the extrusion granulator is small, so it is difficult to achieve large-scale production. Therefore, this method is generally used for the production scale of less than 30,000 tons per year.

This method is mainly used for compound fertilizers such as Ammonium Bicarbonate.

Things You Need To Pay Attention In Wet Granulation Process

Drying process

First, in drying process , the inlet chute, spiral feed area, and the plate of the dryer are prone to serious scarring problems during the production of high nitrogen products. Therefore, MFP company produce a rotary drum dryer, which is made of carbon steel. In this way, scarring problems can be reduced. However, you need also pay particular attention to clean your dryer, or it would lead to blockage of the discharge port.

High-quality of inner structure can make it possible to evenly feed the material into the plate to ensure that the quality of compound fertilizer production.

Screen process

In terms of the screening processing, you should make sure the correct installation. You need to check and adjust the tilt angle of the screener, ( 45 ° as the best state). When operating, you should carefully check specific vibration impact. The use of the screening machine is essential, as well as the product discharging.

Packaging Process

First of all, place it in a dry and cool room for comprehensive storage to ensure that the looseness of the product is above 95%. Then all kinds of fertilizers should be stored separately and prevent the occurrence of actual accidents. More importantly, you also need to pay attention to the finished compound fertilizer warehouse(avoid the wind and sun, rain and snow leaching) to avoid the loss of fertilizer efficiency, the outer packaging bag weathering damage phenomenon.

All in all, in the compound production line, granulation process is the most important and you can choose fertilizer granulator according to your capacity needs. Also, the quality and capacity of other auxiliary equipment are also worthy of consideration.

If you have any other questions about compound production line, please contact us and our specialists will help you solve your problems.