Screening equipment is essential for the efficient composting of livestock and poultry waste. In the composting process, you have to turn the compost regularly with the compost turners to ensure enough moisture and oxygen. However, if there are a lot of stones or other debris, long-term collision with damage the parts or may reduce the service life of the composting machines.

At the same time, at the end of the composting process, you need to clean out the unreacted large pieces of filler. Therefore, the sieving equipment can not only remove the material in the pre-composting stage to reduce the loss of composting equipment but also in the post-composting stage to ensure the smooth processing of subsequent materials, and recycling fillers to control costs.

WHAT IS THE ADVANTAGE OF A ROTARY DRUM SCREEN?

Rotary screening machine is a common equipment in fertilizer production, mainly used for the separation of finished products and return materials, and also can realize the symmetrical classification of finished products. It has high screening efficiency and become the new favorite of fertilizer production customers.

5 Advantages Of Screening Machine

Application Of Rotary Screening Machine

It is used in fertilizer production, steel making, mining, quarrying, forging, food industry, and the chemical industry. It is used for the separation of materials such as compound fertilizer, organic fertilizer, stone, different kinds of sand, activated carbon, etc.

Working Principles Of Rotary Screening Machine

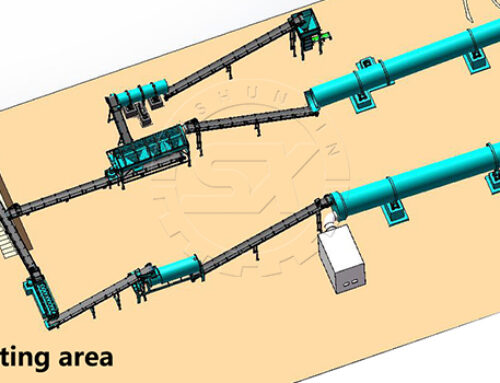

The Rotary Screening Machine is mainly composed of an inlet and outlet, transmission system, sieve cleaning device, frame and outer cover, and drum. The screen cleaning device consists of a screen, screen cleaning brush, support frame, and spring stabilization mechanism.

After the particles enter the screen surface, they are subjected to the friction force provided by the drum and their own gravity. The particles move in a circular motion together with the drum. During the motion, when the combined force is not enough to provide the centrifugal force required for the circular motion. The material particles break away from the drum, shoot out at a certain speed, do a parabolic motion, and return to the screen surface again.

What Will Influence the Efficiency of Rotary Screening Machines?

When the tilting angle of the drum is small, the screening efficiency increases with the increase of the rotating speed of the drum. The speed increase can make the material dispersion, and increase the passing rate. However, when the tilt angle is large, the screening efficiency with the increase of the drum speed is reduced.

When the tilt angle of the drum is certain, the power consumption at the same speed increases rapidly with the increase of the feeding volume. When the feeding volume is certain, with the increase of the drum speed, the power consumption shows a trend of first decreasing and then increasing. Because when the drum speed increases, the material can be screened faster, and most of the qualified material will leave the drum, thus reducing the load of the drum, and the power consumption decreases.

Leave A Comment