15,000 Ton Per Year Poultry Manure Fertilizer Production Line

The annual output of a 15,000-ton poultry manure fertilizer production line is suitable for a medium-scale of poultry farm. In this production line, fertilizer equipment needs to work for 8 hours a day and 330 days a year to reach the 15,000 tons capacity.

It means our fertilizer equipment could process your poultry manure about 5 tons per hour.

The ratio of poultry manure to finished products is generally 3:1, that is, 3 tons of chicken manure produces 1 ton of organic fertilizer. This poultry manure fertilizer production line can assemble a farm with a scale of 150,000 lay chickens. A farm like this can produce about 15 tons of poultry manure per day. Thus, a chicken farm of this scale can produce 15,000 tons of granular fertilizer.

MFP provides various kinds of production lines and it can also assemble your 30,000-ton and 50,000-ton-per-year poultry fertilizer production lines.

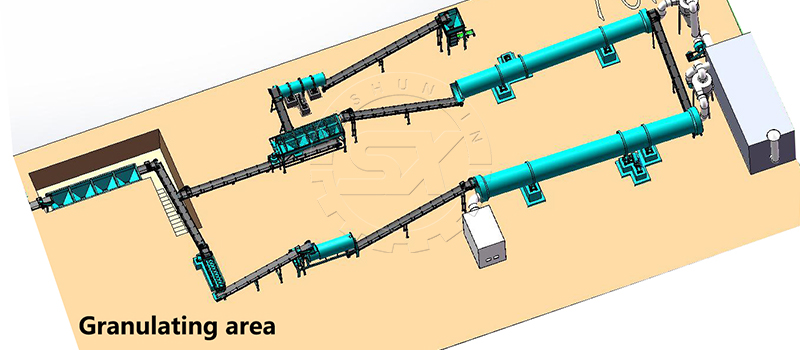

Main Equipment In 15,000 Ton Poultry Fertilizer Granulation Line

Real-life strategy to reach your goals.

The main steps in the poultry manure fertilizer production line include making compost, granulating fertilizer powder, drying and cooling, and packing. In these steps, the main equipment is a compost turner, crusher, mixer, granulator, screener, rotary drum dryer, rotary drum cooler, and packaging machine.

1. Compost Turner With A Capacity Of 5 Tons/ Hour

Unfermented poultry manure contains heavy salts, easy to salinize the soil, and increases the soil salt concentration. Therefore, you need to ferment poultry manure before putting it into use. Compost turners can help speed up fermentation. Crawler-type compost turner is recommended for your large compost area. For a 15,000-ton production line, it can produce 5 tons per hour.

steps of Poultry Manure Fertilizer production line

In a nutshell, except for the coating process, all procedures in chemical fertilizer production are indispensable. Also, if you need an automatic production line, belt conveyors are also essential. Through this production line, you can get your final products in the least labor.

Annual output of 15,000 tons Semi-wet Crusher

You can use a semi-wet material crusher to crush well-fermented poultry manure. This crusher can efficiently crush straws and other bedding in the poultry compost for better granulation. The type of semi-wet crusher with a power of 70 kW is fit for this production line.

Disc Mixer with a capacity of 5 t/h

Disc granulators are specialized in poultry manure mixing. The poultry compost powder gets fully mixed, thus improving the mixing uniformity. The 7.5kw model disc mixer of MFP company can efficiently blend your powder. Moreover, its structure is convenient for transporting materials, for you can feed materials from the and discharge them from the bottom.

4-6 t/h capacity Rotary Drum granulator

The rotary drum granulator is favored for its efficiency and low cost for this granulation line. It makes poultry manure fertilizer particles by way of agglomeration.

Rotary Screening Machine

After granulating, the rotary screening machine screens the granules from the rotary drum granulation. Unqualified granules are sent back to the semi-wet crusher after the screening. The model in the 15,000 tons capacity of rotary screening machine can reach 18 rounds per minute and 3-5 tons per hour.

Rotary Drying Machine

Dry the poultry manure pellet fertilizer with a rotary drum dryer. This step is to reduce the moisture produced by the wet granulation process.

A natural gas burner or a hot blast furnace can be heat sources. The former is environmentally friendly, while the latter is cost-effective.

Energy Costing in The Drying Process

15,000ton poultry fertilizer pellets will cost you about 700,000 m³ natural gas or 150,000L diesel. Besides, you can choose biomass fuel which is the cheapest heat source. MFP’s specialists can provide you with a blueprint for building a hot blast furnace.

Rotary Cooling Machine

The end particles at the discharge end of the rotary drum dryer are about 30- 40° C. Therefore, you need cool the pellets to avoid caking. To reduce fertilizer temperature, a dryer, and rotary drum cooling machine are combined.

Rotary Screening Machine

After drying and cooling, you need to screen the finished products for a second time. Then, the qualified poultry manure fertilizer particles can be sent to the final procedure and unqualified ones are screened out to re-granulate.

Automatic Packing System

Finally, you can pack the poultry manure fertilizer pellets. In this process, you can use automatic granules packing machine. It consists of a feeder, conveyor, sealing machine, and automatic weighing and packing equipment.

Belt Conveyor

After composting, you need a feeder to transport the compost to the granulation and packing line. The materials can be sent automatically by the conveyor belt.

Customers Also Asked

How many workers do you need in this production line?

In this production line, five workers can operate the whole process—one for the composting process, one for feeding materials, and 2 for packing and sewing the final products.

Profit of 15,000-ton poultry manure production line

The price of poultry manure fertilizer in 2023 is about $150-200 /ton and it would be about $2,250,000 to $3,000,000. If you apply all the fertilizer equipment mentioned above, it will cost you about $150,000 to $200,000. You can choose the equipment according to your factory area and budget. Furthermore, MFP can provide you with a detailed suggestions if you still have questions about the process.